Aquaflow Wafer Type Check Valve

350 INR

Product Details:

- Structure Wafer Type Double Plate

- Material Cast Iron, Stainless Steel, Ductile Iron, Carbon Steel

- Power Manual

- Pressure PN10, PN16, PN25

- Media Water, Gas, Oil

- Working Temperature -10C to 180C

- Port Size 2 Inch to 24 Inch (DN50 - DN600)

- Click to View more

X

Aquaflow Wafer Type Check Valve Price And Quantity

- 350 INR

- 10 Piece

Aquaflow Wafer Type Check Valve Product Specifications

- Epoxy Coated / Painted

- Water, Oil, Gas, Industrial Pipelines

- Water, Gas, Oil

- 2 Inch to 24 Inch (DN50 - DN600)

- -10C to 180C

- Round

- PN10, PN16, PN25

- Manual

- Cast Iron, Stainless Steel, Ductile Iron, Carbon Steel

- Wafer Type Double Plate

Aquaflow Wafer Type Check Valve Trade Information

- 50 Piece Per Week

- 1 Week

Product Description

Specification

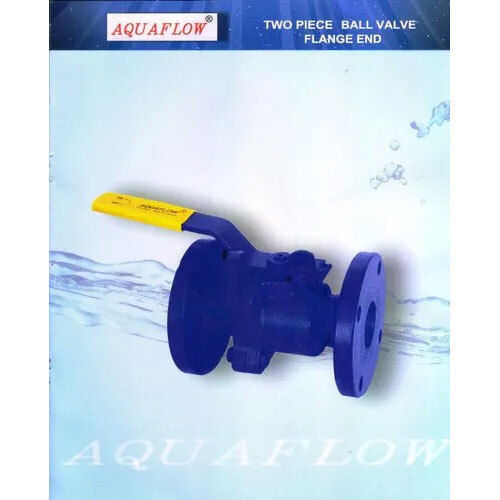

| Model Name/Number | AQUAFLOWWCV |

| Brand | AQUAFLOW |

| Pressure | 150 PSIG |

| Product Type | WAFER TYPE CHECK VALVE STAINLESS STEEL CS & CI |

| Material Grade | STAINLESS STEEL |

| Color | SILVER,BLUE |

| Material | Stainless Steel |

| Size | 50MM TO 600MM |

High Performance & Reliable Sealing

Aquaflow Wafer Type Check Valve delivers exceptional reliability by utilizing durable materials like stainless steel and ductile iron. The valve achieves zero-leakage (bubble-tight) performance with EPDM, NBR, or metal sealing types, making it ideal for critical operations. Its corrosion-resistant surface from fusion bonded epoxy coating further extends product lifespan and efficiency.

Versatile Installation & Broad Application

Designed for flexibility, the check valve supports horizontal and vertical installation and fits a wide range of pipe sizes from 2 to 24 inches. Its wafer-type double plate structure optimizes space and ensures easy integration into industrial pipelines handling water, oil, or gas. Suitable for dealers, distributors, suppliers, and manufacturers across the Indian market.

FAQs of Aquaflow Wafer Type Check Valve:

Q: How is the Aquaflow Wafer Type Check Valve installed in a pipeline?

A: The Aquaflow Wafer Type Check Valve fits between flanges in the pipeline using a wafer end connection. It is designed for both horizontal and vertical installation, facilitating easy integration into new or existing industrial pipe systems.Q: What are the major benefits of using this check valve in industrial applications?

A: This valve provides zero-leakage (bubble-tight) performance, corrosion resistance through fusion bonded epoxy coating, and robust operation for water, oil, and gas pipelines. Its automatic, non-return functionality prevents reverse flow, protecting system components and ensuring reliable operation.Q: When should I choose EPDM, NBR, or metal sealing for the valve?

A: EPDM is ideal for water and mild chemicals; NBR works well with oils and hydrocarbons; metal seating is preferred in harsh environments with elevated temperatures or abrasive media. Selecting the appropriate sealing type depends on your specific application and media handled.Q: Where can the Aquaflow Wafer Type Check Valve be used?

A: It is suitable for water, oil, and gas pipelines in industrial facilities, including power plants, manufacturing units, and municipal systems. The valve is widely supplied and installed by dealers, exporters, manufacturers, and traders across India.Q: What is the face-to-face dimension and why is it important?

A: The valve features a short pattern face-to-face dimension as per ISO 5752 and API 594 standards. This compact design allows for space-efficient installation while maintaining compatibility with standard pipework configurations.Q: What is the typical process for maintaining this check valve?

A: Routine inspection involves checking for seal integrity, ensuring the disc and spring operate smoothly, and verifying the zero-leakage performance. The durable coating and robust materials minimize maintenance frequency, but regular cleaning and operational checks are recommended to prolong service life.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Aquaflow Brand Valves' category

Export Countries :- Uae, Kuwait, Qatar, Bahrain, Saudi Arabia, Turkey, Jordan Egypt, Oman, Iraq, Israel Full, Africa, Azerbaijan, Libya, Tunisia, Morocco, Syria, Iran, Turkmenistan, Uzbekistan, Comoros

Send Inquiry

Send Inquiry Send SMS

Send SMS