Aquaflow Butterfly Valve Manual Gear Operated

350 INR

Product Details:

- Structure Butterfly Valve, Gear Operated

- Material Cast Iron / Ductile Iron / Stainless Steel

- Power Manual, Gear Operated

- Pressure PN10/PN16 Rated

- Media Water, Air, Non-corrosive fluids

- Working Temperature Up to 120C

- Port Size 50 mm to 600 mm (2 inch to 24 inch)

- Click to View more

X

Aquaflow Butterfly Valve Manual Gear Operated Price And Quantity

- 10 Piece

- 350 INR

Aquaflow Butterfly Valve Manual Gear Operated Product Specifications

- Epoxy Coated / Painted

- Water Supply, Sewage, Fire Fighting, HVAC, Industrial Flow Control

- 50 mm to 600 mm (2 inch to 24 inch)

- Cast Iron / Ductile Iron / Stainless Steel

- Water, Air, Non-corrosive fluids

- Wafer / Lug Type

- Up to 120C

- PN10/PN16 Rated

- Manual, Gear Operated

- Butterfly Valve, Gear Operated

Aquaflow Butterfly Valve Manual Gear Operated Trade Information

- 50 Piece Per Week

- 1 Week

Product Description

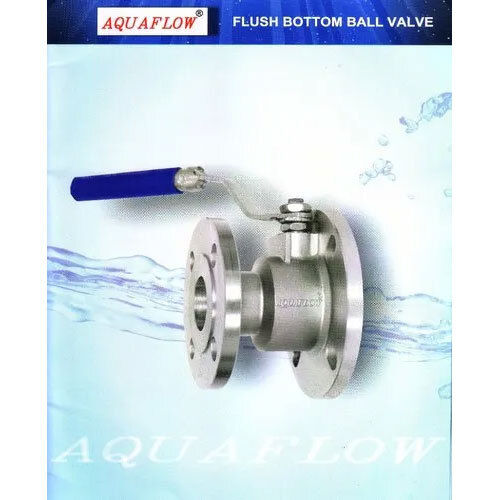

Specification

| Power | Manual |

| Model Name/Number | AQUAFLOWBVM |

| Media | Water |

| Brand | AQUAFLOW |

| Pressure | 150 PSIG |

| Temperature Of Media | High Temperature |

| Operator | Lever |

| End Connection | FLANGE END |

| Construction | Cast Iron |

Efficient Flow Control for Industrial Demands

Aquaflow Butterfly Valve offers dependable manual gear operation, suitable for a range of media including water, air, and non-corrosive liquids. Instant response and enhanced sealing minimize leaks, making it highly reliable for demanding industrial and municipal applications such as water treatment, fire fighting, and HVAC systems.

Durable Construction for Longevity

Engineered with discs made from ductile iron, stainless steel, or aluminium bronze, and seats from EPDM, nitrile, or PTFE, these valves resist corrosion and wear. The fusion-bonded epoxy or rubber lining further increases service life, allowing consistent operation even under high pressure and temperature conditions.

Versatile Mounting and Operation

With ISO 5211 top flange drilling, the valve easily integrates with actuators for automation upgrades. The handwheel gear operation ensures smooth manual control, while the wafer and lug-type connections suit varied pipeline configurations.

FAQs of Aquaflow Butterfly Valve Manual Gear Operated:

Q: How does the manual gear operation benefit industrial flow control?

A: The manual gear-operated handwheel allows precise adjustment of flow rate, easy shut-off, and reliable operation, especially in critical applications where consistent performance is required. This ensures accurate flow management in water supply, sewage, and HVAC systems.Q: What materials are used for the disc and seat, and why are they important?

A: Discs are available in ductile iron, stainless steel, or aluminium bronze, providing corrosion resistance and strength. Seats made from EPDM, nitrile, or PTFE ensure excellent sealing and chemical compatibility, reducing maintenance and enhancing durability.Q: When should I choose a wafer type versus lugged type end connection?

A: Wafer type is ideal for simple applications where the valve is sandwiched between flanges. Lugged type is preferable for cases requiring isolation on both sides or easier maintenance, as the valve can remain intact while removing pipes or flanges.Q: Where can the Aquaflow Butterfly Valve be used?

A: This valve is suitable for water supply, sewage treatment, fire fighting, HVAC, and various industrial flow control processes. Its robust design makes it adaptable for municipal utilities and facility management across sectors.Q: What is the process for mounting an actuator onto the valve?

A: The valve features ISO 5211 top flange drilling, enabling quick and standardized actuator installation. Simply align the actuator mounting holes to the flange and secure using fasteners for automated operation, if required.Q: What is the maximum working pressure and temperature for this valve?

A: The valve operates reliably up to 16 bar differential pressure and withstands temperatures up to 120C, accommodating a spectrum of demanding applications.Q: What are the benefits of the fusion bonded epoxy or rubber body lining?

A: Fusion bonded epoxy and rubber linings protect against corrosion, extending the valves lifespan and maintaining internal surface integrity, especially crucial when installed in harsh or corrosive flow environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Aquaflow Brand Valves' category

Export Countries :- Uae, Kuwait, Qatar, Bahrain, Saudi Arabia, Turkey, Jordan Egypt, Oman, Iraq, Israel Full, Africa, Azerbaijan, Libya, Tunisia, Morocco, Syria, Iran, Turkmenistan, Uzbekistan, Comoros

Send Inquiry

Send Inquiry Send SMS

Send SMS