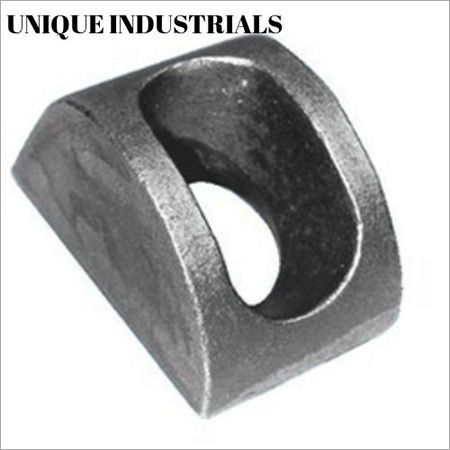

MS Sight Glass

360 INR/Piece

Product Details:

- Weight Variable (Depends on Size)

- Facing Flat Face / Raised Face

- Process Forged

- Heat Treatment Annealed

- Tolerance 0.1 mm

- Design Transparent body with metal frame

- Product Type Sight Glass

- Click to View more

X

MS Sight Glass Price And Quantity

- 360 INR/Piece

- 100 Unit

MS Sight Glass Product Specifications

- 5 mm to 20 mm

- Golden (Metallic)

- Rust preventive coating

- Variable (Depends on Size)

- Polished finish

- Flanged / Screwed

- ASME / DIN / IS

- inch to 6 inch

- 0.1 mm

- Up to 16 bar

- Forged

- Annealed

- Mild Steel (MS Frame) and Tempered Glass

- Transparent body with metal frame

- Sight Glass

- Round

- Flat Face / Raised Face

MS Sight Glass Trade Information

- 10 Unit Per Week

- 1 Days

Product Description

Discover the popular MS Sight Glass, a peerless solution for industrial pipelines in chemical, pharmaceutical, and food industries. Its transparent virtuoso design, featuring top-tier borosilicate or toughened glass, ensures 360 visual inspection of liquids, gases, and steam. Constructed with an MS frame and PTFE gasket for leak-proof, corrosion-resistant, and customizable applications, it supports both vertical and horizontal installation. The polished surface and annealed, tempered glass guarantee longevity, with sizes from inch to 6 inch, heat resistance up to 180C, and operating pressures up to 16 bar. Factory-tested for flawlessness.

Optimal Suitability and Distinguished Features

The MS Sight Glass is perfectly suited for continuous process monitoring in industrial, chemical, and fertilizer pipes. It features a robust, polished metal frame with a transparent glass body, allowing comprehensive surface application. With seamless ANSI/DIN/BS connections, this device excels in vertical or horizontal installations. Its easy-to-remove and clean structure, combined with rust-preventive coating and 0.1 mm tolerance, ensures high reliability and excellent usability in demanding environments.

Sample Policy, Supply Ability, and Export Markets

Our sample policy provides flexible options for product inspection before drop-off. With significant supply ability, we ensure timely fulfillment to both domestic and international clients. MS Sight Glasses are efficiently transported using reputable transport services and are box-packed for optimal protection. Main export markets include Asia, Europe, Africa, and the Middle East. Our professional logistics team guarantees that each delivery, whether small or bulk, meets client expectations and international import requirements.

Optimal Suitability and Distinguished Features

The MS Sight Glass is perfectly suited for continuous process monitoring in industrial, chemical, and fertilizer pipes. It features a robust, polished metal frame with a transparent glass body, allowing comprehensive surface application. With seamless ANSI/DIN/BS connections, this device excels in vertical or horizontal installations. Its easy-to-remove and clean structure, combined with rust-preventive coating and 0.1 mm tolerance, ensures high reliability and excellent usability in demanding environments.

Sample Policy, Supply Ability, and Export Markets

Our sample policy provides flexible options for product inspection before drop-off. With significant supply ability, we ensure timely fulfillment to both domestic and international clients. MS Sight Glasses are efficiently transported using reputable transport services and are box-packed for optimal protection. Main export markets include Asia, Europe, Africa, and the Middle East. Our professional logistics team guarantees that each delivery, whether small or bulk, meets client expectations and international import requirements.

Specification

|

Finishing |

stainless steel , ms |

|

Size |

3/4 inch |

|

Type |

view glass flange end |

|

Usage/Application |

Chemical Fertilizer Pipe |

|

Brand |

ALL |

|

Usage |

Industrial |

|

Material |

MS AND STAINLESS STEEL SS |

FAQs of MS Sight Glass:

Q: How is the MS Sight Glass installed and what connection types are available?

A: The MS Sight Glass is compatible with both vertical and horizontal installations and offers flanged or screwed connections, adhering to ANSI, DIN, and BS standards.Q: What materials and temperature resistance does the sight glass offer for industrial usage?

A: The product consists of a mild steel or stainless steel frame and borosilicate or toughened glass, offering resistance up to 180C, suitable for robust industrial applications.Q: When should I choose customization for MS Sight Glass?

A: Customization is advisable when specialized sizes, coatings, or connection types are required. Our factory can tailor specifications to individual process needs upon request.Q: What makes MS Sight Glass leak-proof and corrosion-resistant?

A: It is factory-tested for leak-proof performance, featuring PTFE gaskets and a rust preventive coating for enhanced corrosion resistance, suitable for harsh chemical environments.Q: Where is MS Sight Glass mainly used and what mediums can be inspected?

A: MS Sight Glass is widely used in chemical, pharmaceutical, and food processing pipelines for the visual inspection of liquids, gases, and steam.Q: What is the process for maintenance and cleaning of MS Sight Glass?

A: Maintenance is straightforward; the device is designed for easy removal, cleaning, and replacement, ensuring minimal downtime during servicing or inspections.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Carbon Steel Reducers' category

Export Countries :- Uae, Kuwait, Qatar, Bahrain, Saudi Arabia, Turkey, Jordan Egypt, Oman, Iraq, Israel Full, Africa, Azerbaijan, Libya, Tunisia, Morocco, Syria, Iran, Turkmenistan, Uzbekistan, Comoros

Send Inquiry

Send Inquiry Send SMS

Send SMS